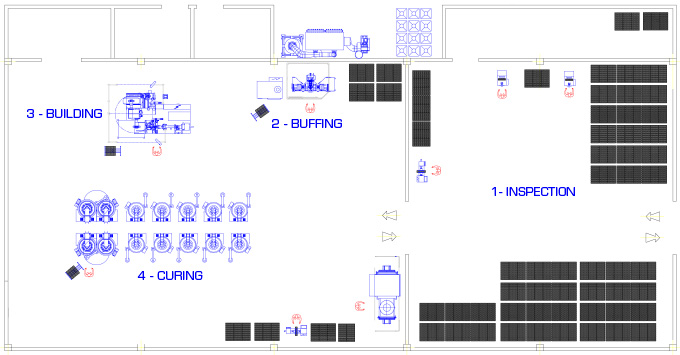

The retreading of passenger, light truck and 4x4 tires is normally done only with the hot method. Casings are going through an initial visual inspection which sometimes is also supported by a pressure test; at this stage some casings will be rejected while the others will go to the next step of the process, the buffing. On the buffing machine the residual tread is removed and the two sidewalls are brushed.

After buffing the process foresees the casings preparation, with the activities of skiving, repairing, filling and cementing, all aimed at having the casing ready for the building process.

In the retreading business there are several methods of building the tire, in our range we offer what we believe is the most advanced technology, that is the application by a cold feed extruder with the strip winding method; the sidewalls can be applied manually or with an extruder, and the final result is a tire newly built from bead to bead.

The built tire is then moved on the final step of the process, the vulcanization in

curing presses with the selected mold according to the patterns desired.